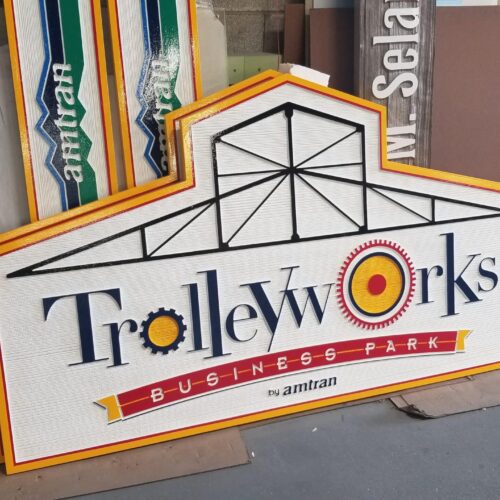

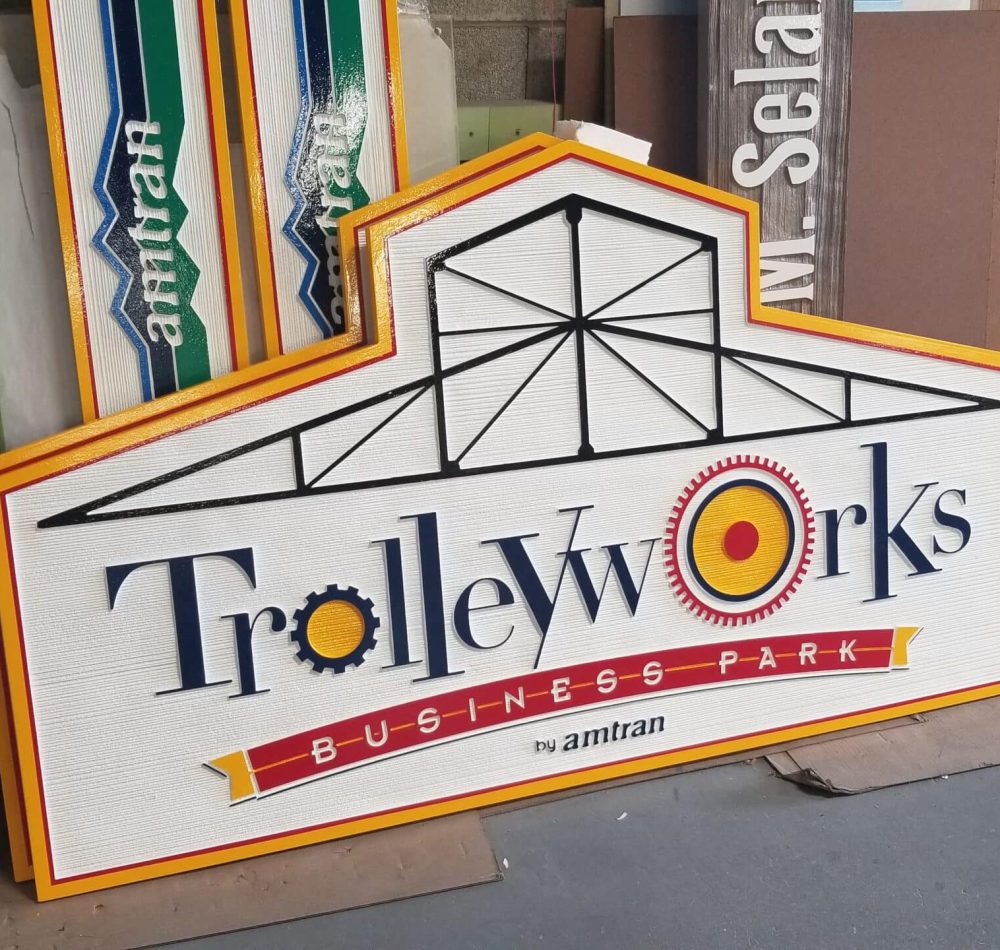

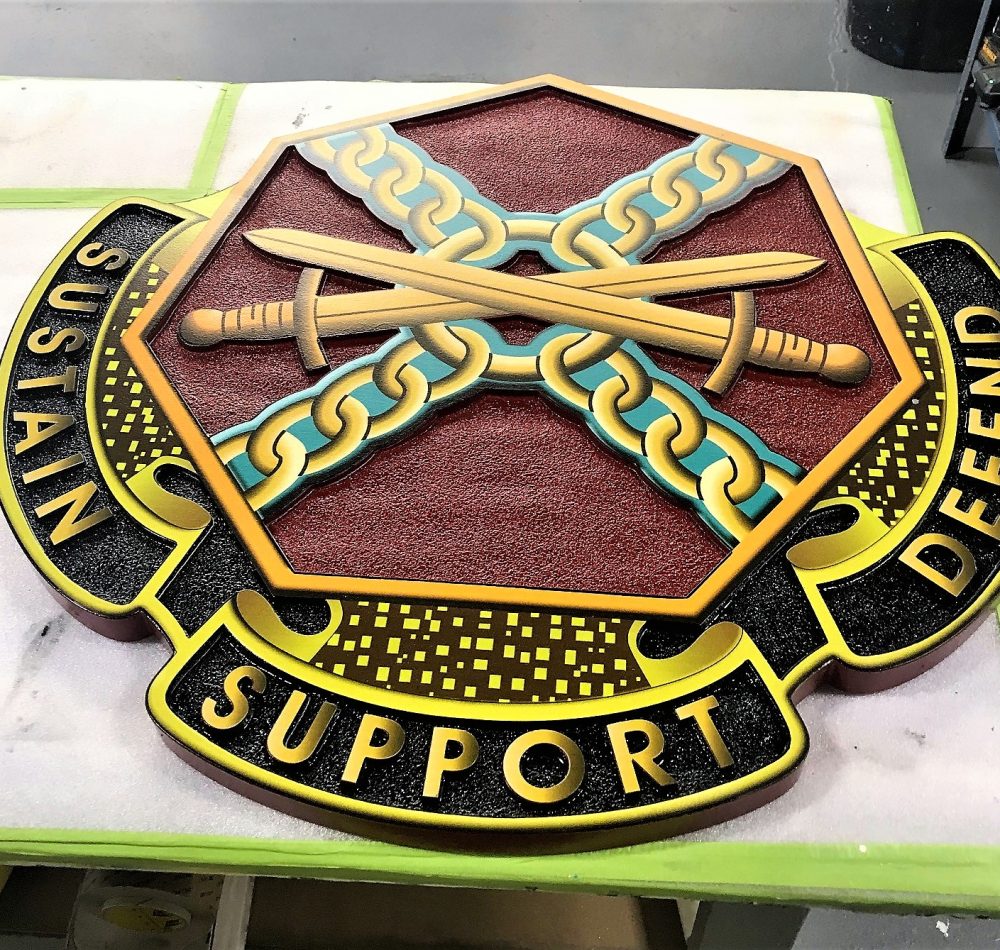

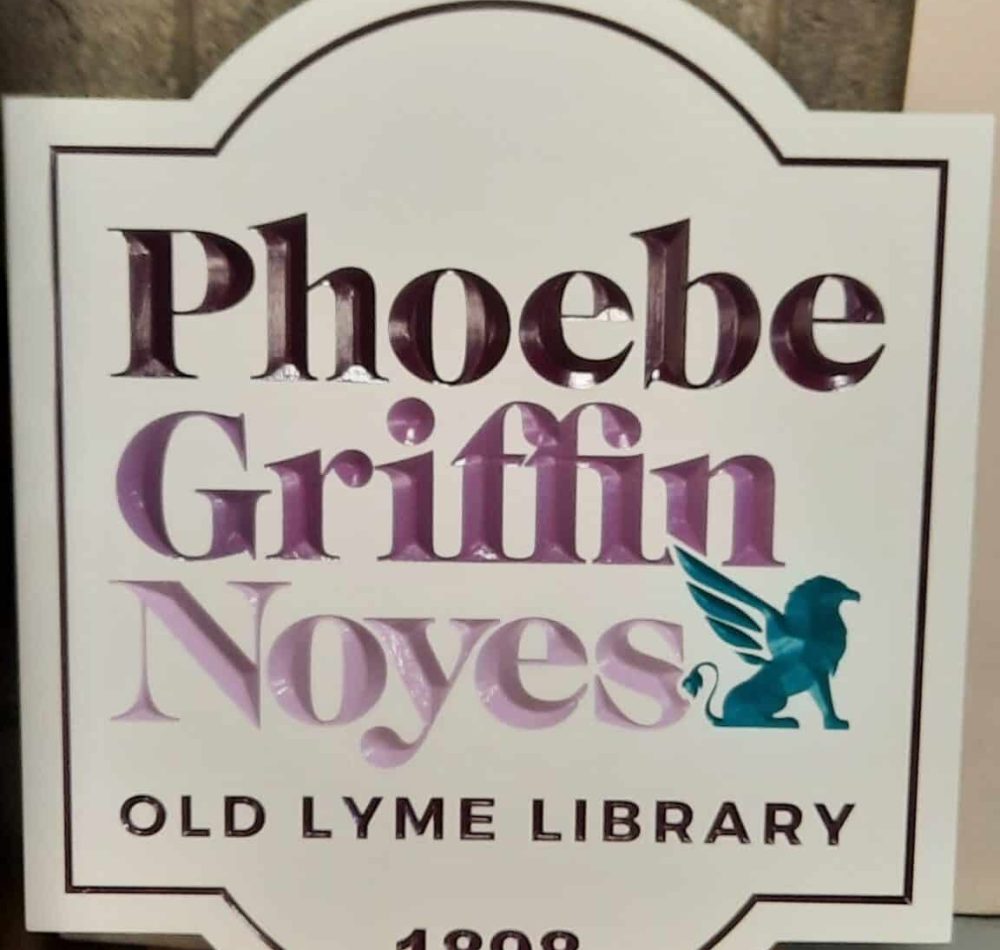

Dimensional Signs

When your clients need the highest quality, longest lasting V-Grooved Signs, Carved Signs, Sandblasted Signs, Architectural Signs or Dimensional signs, Hanson Sign Companies is the name to remember for Dimensional Signs made by the hands of true craftsmen and women. We allow you to offer a full range of substrates from Cedar to HDU and Extira.

Dimensional Signs Applications

Suitable for both indoor and outdoor use; on the side of a building, storefront, reception area, lobby, post and panel or tenant sign.

What is Included

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Brochure

Download our document to see specific data of the service and how we work.

Your Partner for Wholesale Signage

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

82 Carter St, Falconer, NY 14733

Why Sell Dimensional Signage?

Dimensional Wood or HDU Signs that are sandblasted or V-Grooved make a great addition to your product offering. They are among the least complex signs you can sell, easy to understand, one piece with no parts or electronics to break or wear out, easy to install with great margins and provide your customers with a unique, classic and distinctive image. Dimensional signage can have a great impact on a company’s branding and marketing. Well-designed and imaginatively displayed, dimensional signs will catch the eye and are generally easier to read and more memorable than other signs.

How are Dimensional Signs Made?

Dimensional signs are most commonly fabricated using 3 different substrates which are sandblasted, V-grooved, or both. The signs are then primed and have spray painted or stained backgrounds with hand painted or gold leaf lettering and logos.

Overall, dimensional sign manufacturing requires a combination of skilled craftsmanship, advanced technology, and attention to detail to create visually appealing and durable signage that effectively communicates messages and enhances branding efforts.

What Materials are used to Manufacture Dimensional Signs?

Cedar

Variation in wood grain is common as cedar blanks are made from assorted planks – natural finishes that show the grain and color variance can be an advantage or disadvantage depending on the look the customer wants. It is important to manage expectations – color variation is natural, common and can’t be prevented.

Rot resistant

Excellent for sandblasting and V-grooving

Wood itself usually lasts 15-20 years outdoors

Medium to high impact resistance

Most expensive of the substrates

Harder to acquire

Only available in 10’ lengths or less

Not a lot of grain variation

Only available in 1.5” thickness

HDU

HDU, or High-Density Urethane, is a versatile material used in dimensional signage manufacturing. It is a lightweight, durable, and weather-resistant material that can be easily shaped and carved to create intricate designs. HDU is commonly used for its ability to mimic the look of traditional materials like wood, while offering superior longevity and ease of use.

- Man made, does not rot, deteriorate or crack

-Ranges in thickness of 1” – 3”

-Excellent for sandblasting and V-grooving

-Softer material, easier for graphics at different depths use epoxy with fasteners

-Available in different densities

-2 different background patterns for sandblasting (pebble or grain)

-Over 10’ length requires a seam

-Can be broken or bent more easily

-Install must have pre-drilled holes

Extira Dimensional Signs

Extira is an innovative composite material used in dimensional signage manufacturing. It is made from sustainable wood fibers, phenolic resins, and zinc borate, making it highly durable and weather-resistant. Extira is ideal for outdoor signage due to its ability to withstand moisture, rot, and termites. It can be painted, routed, and carved to create intricate designs, making it a popular choice for dimensional signage that requires longevity and a high-quality finish.

-Man made, does not deteriorate or crack

-Available in lengths up to 16’ long

-Manufacturer’s warranty of 5 years

-Most cost effective of all substrates for v-Groove thickness

-Great for single sided V-groove routing

-Highest impact resistance

-Sandblasting adds cost due to timerequired on very hard material

-Not ideal for 2 sided signs due to 1.25”

-Heaviest material (~50%/sq ft. more)

Dimensional Signage Manufacturing Process

Dimensional signs are manufactured through a multi-step process that involves design, material selection, fabrication, painting, finishing, and installation. Here’s an overview of the typical manufacturing process for dimensional signs.

1. Design Phase

The process begins with the creation of a design concept based on the client’s specifications and requirements. Designers may use computer-aided design (CAD) software to create detailed renderings of the sign, taking into account factors such as size, shape, materials, and aesthetics.

2. Material Selection

Once the design is finalized, appropriate materials are selected based on factors such as durability, weather resistance, and desired appearance. Common materials used for dimensional signs include wood, metal, plastic, acrylic, PVC, foam, and composite materials.

3. Fabrication

Fabrication of dimensional signs involves cutting, shaping, and assembling the selected materials according to the design specifications. Advanced manufacturing techniques such as CNC routing, laser cutting, thermoforming, or vacuum forming may be used to create intricate shapes and details. Components such as letters, logos, and background panels are fabricated separately and then assembled to create the final sign.

4. Painting & Finishing

Once the components are fabricated, they are prepared for painting and finishing. Various painting techniques such as spray painting, screen printing, or digital printing may be used to apply colors, logos, and graphics to the signage. Finishing touches such as sanding, polishing, or applying protective coatings help enhance the appearance and durability of the sign.

5. Installation

Proper installation is crucial to ensure that the dimensional sign is securely mounted and effectively communicates its message. Installation techniques vary depending on the type of signage and its intended location. For example, indoor signs may be mounted using adhesive tapes or standoffs, while outdoor signs may require anchoring systems or mounting brackets. Installation may also involve electrical work for signs that incorporate lighting elements such as LED lights or neon tubes.

6. Quality Control & Testing

Throughout the manufacturing process, quality control measures are implemented to ensure that the dimensional sign meets the desired standards for appearance, functionality, and durability. Testing may be conducted to assess factors such as structural integrity, weather resistance, and electrical safety for signs with lighting components.

What is Included

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Hanson Sign Companies

EXPAND YOUR CAPABILITIES.

We will get back to you with 1-2 business days. Or just call us now.